Choosing the right abrasives will ensure that ideal sanding results can be achieved quickly and economically. There are many variables which effect the performance and durability of sandpaper, so comparing price per piece is not an effective method. Let's look at some of those variables to help you decide which is the best for you.

What is sandpaper grit really made of?

Today's sandpapers don't actually use sand for the abrasive. Instead, they use more abrasive grit that is sharper, longer-lasting, and friable (meaning that it breaks to expose new sharp edges).

Aluminum oxide is the most widely-used abrasives when it comes to sandpaper. It is a man-made grain that is economical and versatile - usable on a wide range of materials including drywall, wood, paint and metal. It rates around 9 on the Mohs Scale of Hardness (diamond is rated at 10). This abrasive may be white, pink, red or brown.

Silicon carbide is the hardest commonly abrasive grain, other than diamond, with a rating of 9.5 on the Mohs Scale of Hardness). It is ideal for use on harder surfaces like metal, glass, stone and marble, and between coats of finish. This abrasive is usually gray, blue-gray or black in colour.

Ceramic aluminum grit, often referred to as ceramic, is extremely durable but less friable than aluminum oxide or silicon carbide. At 9 on the Mohs Scale of Hardness, it is ideal for hard materials and usually red/brown in colour.

Which grits should I be using?

Coarser abrasives have a lower number (such as Festool's P24 grit Saphir) and finer abrasives have a high number (such as Mirka's 4000 grit Abralon). Coarse abrasives generally cut more quickly and leave deeper scratches, but type of grit, backing, and other design factors can impact the speed of cut.

Mirka Abralon P4000 and Festool Saphir P24

Generally, but dependent on the application:

- 24 to 80 grit sandpaper is ideal for shaping and stripping paint.

- 100 to 120 grit sandpaper is ideal for smoothing

- 150 to 240 grit sandpaper is ideal for finish prep

- 280 to 4000 grit sandpaper is ideal for sanding between coats of finish and controlling sheen

Keep in mind that your particular application will have a 80 or 120-grit might be fine enough for finish sanding for a floor, but for furniture, you may want to sand to 180 or higher depending on the finishing schedule.

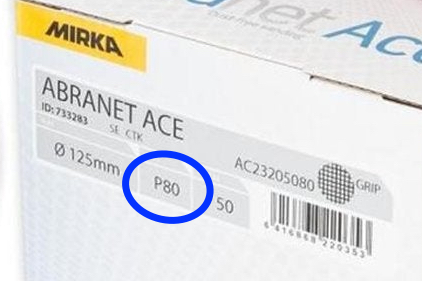

What does the P mean?

You've probably noticed that the grit of some sandpaper is preceded by the letter "P". The "P" means that the abrasive is produced to the standards set out by the Federation of European Producers of Abrasives (FEPA). The standards state strict tolerances of grit sizes, which means greater uniformity grit size, and therefore, scratch pattern.

P = greater uniformity of grit particle size = more consistent scratch pattern

Do I want open or closed coat?

The terms open and closed coat refer to how much space there is between the grit particles.

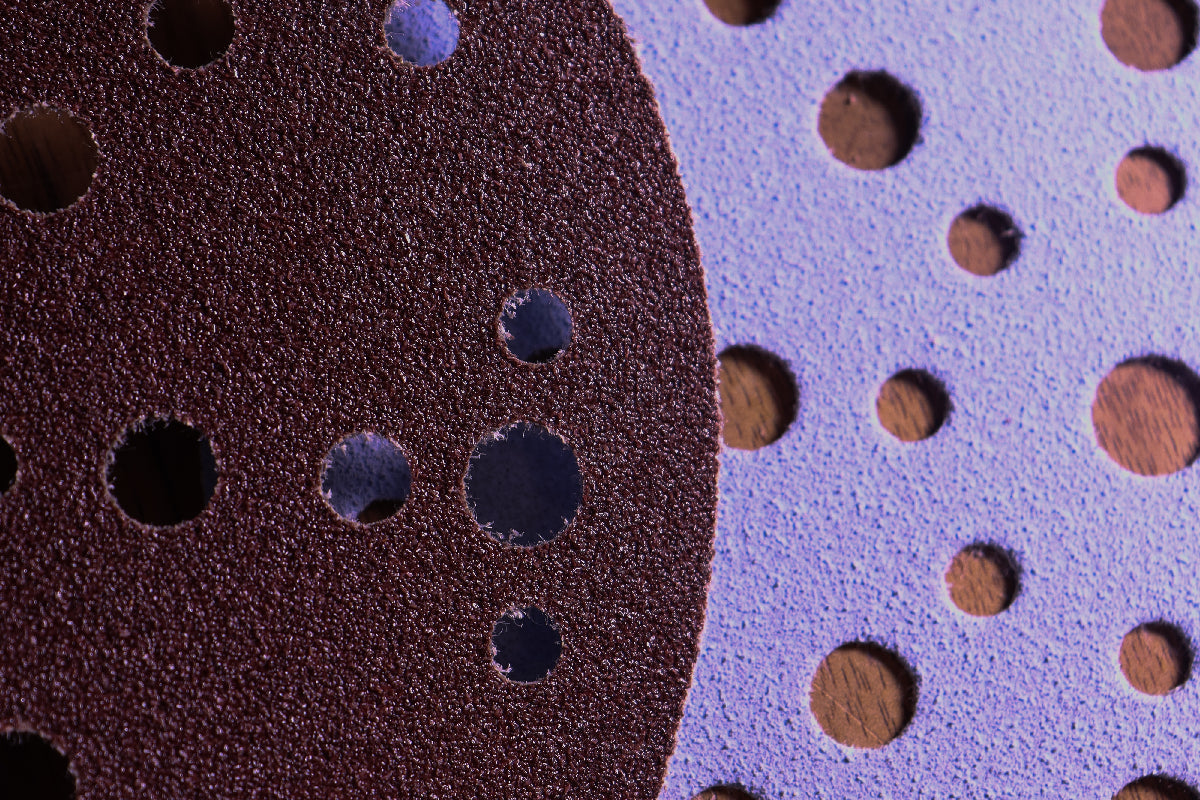

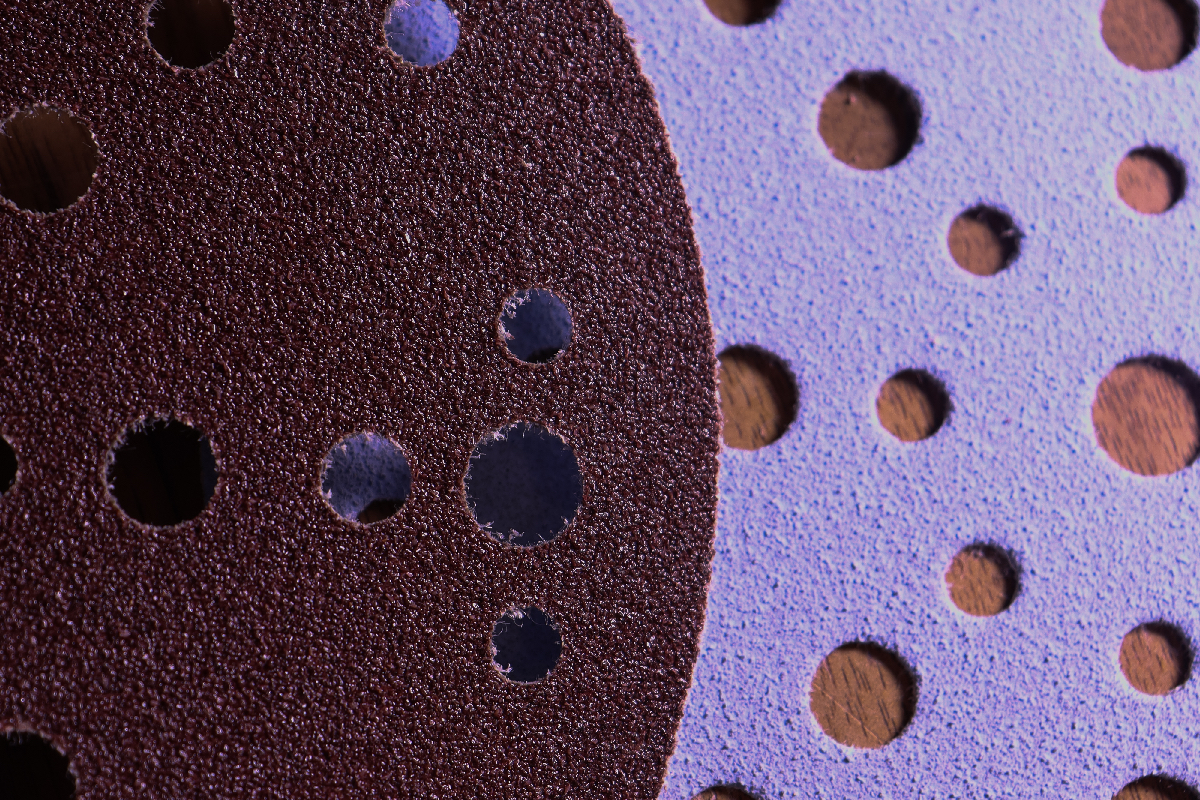

The red Festool Saphir disc below has a semi-closed coat, with lots of grit on the disc. A closed coat generally results in longer abrasive life and a finer finish than an open coat disc with the same grit.

More grit = longer disc life & smoother surface

On the other hand, the blue Festool Granat disc has an open coat with lots of space between grit particles. This provides more room for sanding swarf (e.g. dust) so the cutting action of the disc is less affected.

Less grit = less loading & more effective sanding

Why is the backing material important?

The backing material of the abrasive plays a significant role in the performance of the sandpaper.

A really good example is a foam hand sanding block. If you use your fingertips to feel the grit, you might say that it is very coarse. However, because of the softness of the foam, the scratch pattern left by the block is quite fine.

Paper backing are common for general-purpose sandpaper. For manual hand sanding, have a look at Mirka's Gold Proflex sheet sandpaper which has a unique anti-slip coating on the back which makes hand sanding a little easier and less straining.

While most sandpaper does have paper for a backing, many heavy duty abrasives such as belts and Festool's Saphir use a cloth backing that is tougher and more tear-resistant, so the disc itself lasts at least as long as the abrasive on its face. Thicker backings are usually stiffer, so conform less well to contoured surfaces.

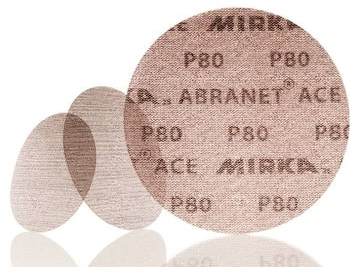

Mirka was the first to develop mesh backings for sandpaper. A mesh abrasive doesn't have a regular hole pattern, so the abrasive is spread consistently across the surface, there are no holes to catch on an edge, no fuss to align with the holes in the sander pad, and dust can pass through the entire surface so dust extraction and cleaning the sandpaper is easier.

What kind of bonding resin is best?

The bonding resin is probably the unsung hero of sandpaper. It holds the grit to the backing.

Remember that foam sanding block we talked about? The flexibility of the foam backing allows you to bend the whole sanding block so that contours can be sanded uniformly. The bonding resin has to be flexible enough to allow that flexing or else the abrasive will crack and peel off the foam block.

In addition, too strong a bonding resin not release worn-out particles of grit, reducing the efficiency of sanding and too weak a bonding resin will release them prematurely, reducing the working lifespan of the sandpaper.

What different ways are there to attach the sandpaper to a sander?

How the sandpaper is held is not insignificant, and not only affects the convenience of use, but the surface quality too.

In the past, all sandpaper was attached with adhesives (e.g. pressure-sensitive or contact adhesives). However, for handheld electric sanders, hook and loop (e.g. Velcro) fasteners for sandpaper has become the norm as it allows simple attachment and removal over and over again.

But not all hook and loop systems are the same. Mirka's sanding pads use a pattern of alternating hooks to grip the loop backing of the abrasive more securely (just like cross nailing).

Close-up of Mirka's hook pattern |

20x magnified top-down view of Mirka's hooks |

Festool's StickFix hook technology also uses an alternating pattern, but uses lower-profile hooks which resulting in less cushion beneath the abrasive surface and allowing a firmer (and flatter) sanding disc.

|

Close-up of Festool's hook pattern |

20x magnified top-down view of Festool's hooks |

Don't forget about the sander!

Not only does the sander ergonomically hold the sandpaper and move it to save you effort, but good electric sanders and sanding blocks extend the life of the sandpaper and keep the environment cleaner. More on that in another Spotlight!

We stock the full range of grits for your sanding and polishing needs

Shop online by abrasive shape. Contact us if you need more information, or help choosing the right abrasives for your project.